media coverage

"Why are there renewed odor complaints from nearby residents?"

"Why does the air remain pungent despite continuous and large-scale deodorant spraying?"

"Why did we fail the environmental inspection and receive a rectification notice?"

If you are a manager of a waste transfer station or waste treatment facility, these situations are likely all too familiar. Despite substantial investment in deodorizing agents and spraying systems, odor issues often persist and recur. So where does the real problem lie?

In many cases, it is not a lack of effort or budget, but the fact that the deodorization solution was improperly selected from the very beginning.

1. Common Deodorization Pitfalls

Odors in waste transfer stations and treatment facilities are not caused by a single substance. They are a highly complex mixture of hydrogen sulfide (H2S), ammonia (NH3), mercaptans, fatty acids, and various volatile organic compounds (VOCs), forming an intense and persistent odor load. Many odor control failures are not due to insufficient management, but rather to inappropriate deodorizer selection.

Pitfall 1: Relying on Fragrance-Based Masking Agents

Strong fragrances may temporarily mask odors, but they do not eliminate odor-causing molecules. Instead, they often create an unpleasant mixture of fragrance and odor, resulting in secondary olfactory pollution and increased complaints.

Pitfall 2: Blind Adoption of Biological Deodorizers

Biological deodorization depends on microbial activity to degrade odor compounds. However, waste facilities often experience significant fluctuations in temperature and humidity, which can inhibit or deactivate microorganisms, especially during high-temperature conditions or peak odor loads.

Pitfall 3: Choosing Low-Concentration Products Based on Price

Low-concentration deodorizers lack sufficient active ingredients to handle high odor loads. As a result, frequent application is required, operating costs increase, and effective odor control is still not achieved.

Pitfall 4: Using Inferior Chemical Deodorizers

Some inferior chemical deodorizers may contain excessive heavy metals or highly corrosive substances, which can damage spraying equipment and pose risks to soil, water, and the surrounding environment.

Why Does Heavy Investment Still Deliver Poor Results?

This is because: the deodorization approach does not match the actual odor composition and operating conditions. Odor control, like medical treatment, must be accurately targeted to be effective.

2. True Root-Cause Odor Control|Comes from Better Science, Not More Spraying

In waste transfer stations and treatment facilities, odor emissions are complex, highly concentrated, and continuously released. Effective deodorization is not about masking odors, but about decomposing and transforming odor-causing molecules at the molecular level.

From Conventional Thinking to Nature-Inspired Technology

TakingPolymer Plant-Based Deodorant as an example, we move beyond traditional approaches such as fragrance masking or aggressive chemical neutralization, and instead harness the power of nature to deliver a safer, more stable, and more sustainable odor control solution.

Core Mechanism: Molecular Decomposition, Not Odor Overlay

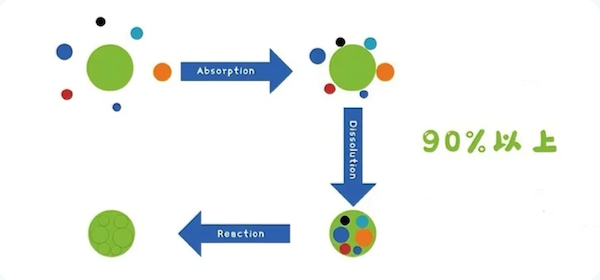

The product is formulated from natural plant sources -including trees, herbs, and flowers -extracting aromatic organic active compounds. Through scientific modification and optimized blending, their reactivity toward odor molecules is significantly enhanced. During atomized spraying, the solution forms micron-sized droplets that fully contact airborne odor molecules. Through Van der Waals adsorption and subsequent chemical reactions, odor-causing compounds such as hydrogen sulfide and ammonia are decomposed into odorless and harmless substances, achieving deodorization without introducing additional fragrances.

Key Advantages

1) Highly Effective Against High-Intensity Odors

Designed for high-load environments such as waste transfer stations and landfills, the plant-based

deodorant delivers rapid action against stubborn odors like hydrogen sulfide and ammonia, achieving broad-spectrum deodorization with overall odor removal efficiency exceeding 90%.

2) Stable Performance Across All Scenarios and Conditions

The product performs reliably in open landfills, enclosed waste rooms, compression workshops, and leachate treatment areas. It remains effective under extreme heat or high humidity, providing comprehensive odor control throughoutthe entire waste management process -from collection to treatment.

3) Dual Assurance of Environmental Safety and Human Health

Formulated from plant-derived ingredients, the deodorant is non-irritating, non-corrosive, and biodegradable, posing no risk of secondary environmental pollution.

The product has been tested and certified by the Chinese Center for Disease Control and Prevention (China CDC):

- No skin irritation in acute rabbit skin irritation tests

- Classified as practically non-toxic in acute oral toxicity tests in mice

3. Proven Performance: Real-World Validation of Plant-Based Deodorizers

Case 1: Multiple Waste Transfer Stations in a Municipality

Project Background: The stations previously relied on fragrance-masking deodorants, resulting in limited odor control performance. Issues such as clogged nozzles and insufficient spray coverage led to frequent complaints from nearby residents and increased regulatory pressure.

Solution: After an on-site assessment, thePolymer technical team optimized the spraying system by upgrading to high-pressure fine mist nozzles and applying a plant-based liquid deodorizer to ensure effective contact and reaction with odor molecules.

Results:

- Odors were no longer perceptible at the site

- Resident complaints were significantly reduced

- The results were officially acknowledged by the local environmental sanitation authority

Case 2: Large-Scale Waste-to-Energy Incineration Plant

Project Background: Key areas such as the waste pit and unloading hall, covering approximately 100,000 m², suffered from severe uncontrolled odor emissions, significantly impacting both on-site conditions and the surrounding environment.

Solution: A misting deodorization system usingPolymer plant-based liquid deodorizer was installed in critical zones for continuous and systematic odor control.

Results:

- Overall odor concentration reduced by more than 80%

- Boundary odor concentration consistently maintained at ≤20 (dimensionless)

- Long-term compliance with environmental regulations achieved

Case 3: Leachate Treatment Workshop at a Landfill Site

Project Background: The landfill processes approximately 350 tons of waste and 12 tons of leachate per day. Prior to treatment, no deodorization measures were in place, and organized odor emissions reached a total concentration of 5,000 (dimensionless).

Solution: Polymer plant-based liquid deodorizer was applied through a targeted misting system in the leachate treatment workshop.

Results:

- Odors inside the workshop became barely perceptible

- Outlet odor concentration reduced to below 500 (dimensionless)

- Insignificant improvement in both working conditions and emission performance

4. Choosing the Right Plant-Based Deodorizer: Three Key Steps

Step 1: Review the Core Ingredients

Choose products that clearly state plant-derived active ingredients, rather than synthetic fragrances. High-quality plant-based deodorizers will transparently disclose theirbotanical sources (such as citrus peels, tea extracts, bark, or herbs) and identify the functional active compounds, ensuring both effectiveness and safety.

Step 2: Clarify the Deodorization Mechanism

Ask suppliers whether their product eliminates odors through chemical decomposition and molecular transformation, or merely masks them with fragrance. Reliable suppliers should be able to provide independent third-party test reports, demonstrating verified removal efficiencies for key odorants such as hydrogen sulfide and ammonia.

Step 3: Verify Practical Application Cases

Request documented cases in similar waste management scenarios, such as transfer stations, landfills, incineration plants, or leachate treatment facilities. Whenever possible, on-site inspections or reference visits can further validate long-term performance under real operating conditions.

5. Effective Odor Control Is a Long-Term Commitment

1) High Dilution Ratio, Lower Cost

With dilution ratios of1: 500~1:1000, one container can replace approximately three conventional deodorant products, delivering superior cost-efficiency.

2) Easy Integration, Minimal Modification

No equipment retrofitting required. The product can be seamlessly integrated into existing spraying or misting systems, reducing labor and operational complexity.

3) Customized Solutions and Professional Support

Our technical team conducts on-site assessments to design tailored deodorization solutions, providing ongoing support to ensure long-term compliance and performance.

Stop increasing operational costs with ineffective deodorization measures. Now is the time to rethink your approach and adopt a more scientific, sustainable solution.

Contact us today

Based on the actual operating conditions of your waste transfer station or treatment facility, we offer a free odor control assessment and product trial, helping you achieve compliant, efficient, and long-term odor management.

Let science and nature work together.

With safer products and proven technologies, we help you eliminate odor problems at their source and safeguard the surrounding environment and public well-being.